Industrial Valve

Industrial valves are used across all industries and form the backbone of all piping systems and networks for controlling flow. There is a huge reliance on mechanical industrial valves for everyday operations across many sectors. Since they do not rely on external power, they are essential safety components preventing backflow, siphonage, air accumulation or for isolating systems during breakdown or maintenance.

Isolation Valve

Isolation Valve

Isolation valves are used in fluid handling systems that stop the flow of process fluid to a given place for maintenance, breakdown or diverting flow. Different types of isolating valves have different opening and closing mechanisms.

Ball valves use a rotary ball design as the main component of the valve. Butterfly valves are designed with a disc that rotates to close perpendicular to the flow. Gates valves open and close with a gate wedge perpendicular to the flow direction. Pinch valves use a rubber sleeve to pinch close either by the application of fluid pressure or mechanically in the body.

Product Specifications available for Isolation Valve

Types of isolation

valve available:

Ball

Butterfly

Gate

Mechanical Pinch

Materials available:

PP / PP-H / U-PVC

PVC / CPVC

Brass

Bronze

Ductile & cast iron

Stainless steel 304, 316

Nickel-aluminium bronze

Sizes

available:

DN8 to DN1800

Max operating

pressure available:

Up to 63 bar

Max operating temperature

available:

-25 °C to 180 °C

Connections available:

Flanges PN10, PN16

Flanges class 150

Threaded BSP, NPT

Spigot

Socket solvent welding

Double flanged

Lugged

Wafer

Suitable media

types:

Water / Waste water

Compressed air Corrosive fluids

Acids & alkalis

Oils / Sludge

Ceramics

Granulates / Pellets

Check Valve

Check Valve

Check valves are installed in a pipeline to prevent reverse in fluid flow. A check valve allows flow only in one direction through either its single, double disc or ball design. When there is reverse fluid flow, the disc or ball closes against the valve seat, sometimes with the help of a spring or a counterweight.

Product Specifications available for Check Valve

Types of check valve:

Ball check valve

Tilting disc check valve

Dual plate check valve

Silent check valve

Swing check valve

Materials available: Bronze

Cast iron

Ductile Iron

DZR bronze

Stainless steel 316

PVC

Sizes available: DN10 to DN1400

Max operating

pressure available:

Up to 40 bar

Max operating temperature available:

-20 °C to 180 °C

Connections available:

Flanges PN10, PN16,

PN25, PN40

Flanges class 150

Threaded BSP

Suitable media

types:

Water

Waste water

Oil

Gas

Chemicals

Backflow Preventer

Backflow Preventer

Backflow preventers stop backflow from happening when there is undesirable reversal of flow of a liquid, gas, or suspended solid into a potable water supply during backsiphonage and backpressure. Backflow preventers function similarly to double check valves with the addition of a reduced pressure zone assembly. When a backflow occurs, both check valves close and the relief valve opens to release the water.

Product Specifications available for Backflow Preventer

Materials available: Gunmetal

Stainless Steel

DZR Brass

Ductile Iron

Bronze

Sizes available: DN15 to DN250

Max operating

pressure available:

Up to 10 bar

Max operating temperature available:

Up to 65 °C

Connections available:

Flanges PN10, PN16

Flanges class 150

Threaded BSP

Suitable media

types:

Potable water

Air Valve &

Vacuum Breaker

Air Valve & Vacuum Breaker

Air valves prevent air accumulation and air locks during filling up of the pipeline by discharging the air through its orifice. When the pipe is fully filled with water, a ball float closes against the orifice in the air valve.

Vacuum breakers prevent back siphonage and negative pressure which can contaminate and collapse a piping system by allowing air to enter the pipeline. This happens when there is a pressure drop upstream of the pipe.

Product Specifications available for Air Valve & Vacuum Breaker

Materials available:

Ductile iron

Brass

Bronze

Plastic

Stainless Steel

Sizes available: DN8 to DN250

Max operating

pressure available:

Up to 40 bar

Max operating temperature available:

Up to 70 °C

Connections available:

Flanged PN10, PN16,

PN25, PN40

Threaded BSP

Suitable media types: Water

Waste water

Strainer

Product Specifications available for Strainer

Sizes available: DN40 to DN600

Max operating

pressure available:

Up to 25 bar

Max operating temperature available:

Up to 70 °C

Connections available:

Flanged PN10,

PN16, PN25

Suitable media

types:

Water

Waste water

Materials available: Ductile Iron

Flap Valve

Product Specifications available for Flap Valve

Materials available: Ductile Iron

Galvanized steel

Stainless Steel 304, 316

Sizes available: DN50 to DN1200

Max operating

pressure available:

Up to 0.6 bar

Max operating temperature available:

Up to 60 °C

Connections available:

Flanged PN10, PN16

Suitable media

types:

Water

Waste water

Slightly corrosive fluids

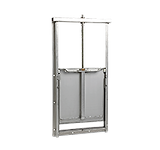

Penstock

Product Specifications available for Penstock

Body materials

available:

Stainless Steel 304, 316 Mild Steel

Seal materials

available:

EPDM

NBR

PTFE

Sizes available: 150mm x 150mm to

3000mm x 3000mm

Max operating

pressure available:

Up to 1 bar

Suitable media

types:

Water

Waste water

Slightly corrosive fluids